Mold Star 15 Slow Moldmaking Silicone Rubber – Trial Unit

$37.44 $28.70

Brand: Smooth

Color: Mold Star 15 Liquid Rubber

Features:

- Tear Resistant – Mold Star silicones cure to soft, strong rubbers which are tear resistant and exhibit very low long term shrinkage *Packaging may vary*

- Heat Resistant – Cured Mold Star rubber is heat resistant up to 450°F (232°C) and is suitable for casting low-temperature melt metal alloys

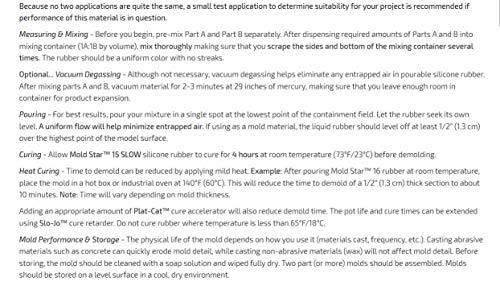

- Curing – Allow Mold Star 15 SLOW silicone rubber to cure for 4 hours at room temperature (73°F/23°C) before demolding.

- Vacuum Degassing – Although not necessary, vacuum degassing helps eliminate any entrapped air in pourable silicone rubber

- Mold Performance – The physical life of the mold depends on how you use it (materials cast, frequency, etc.). Casting abrasive materials such as concrete can quickly erode mold detail, while casting non-abrasive materials (wax) will not affect mold detail. Before storing, the mold should be cleaned with a soap solution and wiped fully dry. Two part (or more) molds should be assembled. Molds should be stored on a level surface in a cool, dry environment

Details: Mold Star rubbers are easy to use platinum silicones which are mixed 1A:1B by volume (no weighing scale necessary). Mold Star silicones feature relatively low viscosities and vacuum degassing is not required for most applications. Mold Star silicones cure to soft, strong rubbers which are tear resistant and exhibit very low long term shrinkage. Molds made with Mold Star will last a long time in your mold library and are good for casting wax, gypsum, resins, concrete and other materials. Cured Mold Star rubber is heat resistant up to 450°F (232°C) and is suitable for casting low-temperature melt metal alloys. Note: THI-VEX is NOT compatible with Mold Star rubbers.MIX RATIO: 1:1 by volume; POT LIFE: 50 mins; DEMOLD TIME: 4 hrs; SHORE A: 15; COLOR: Green

EAN: 0751635292413

Package Dimensions: 9.4 x 9.0 x 3.5 inches

Binding: Office Product

Reviews

There are no reviews yet.